Iintambo zonxibelelwano ezisebenzisa ubuninzi obuphezulu kunye nelahleko ephantsi zihlala zenziwe nge-polyethylene ene-foam okanye i-polypropylene ene-foam njengezinto zokukhusela, iintambo ezimbini zokukhusela kunye nentambo yomhlaba (imarike yangoku inabavelisi abasebenzisa umhlaba ophindwe kabini) kumatshini wokujija, i-foil ye-aluminium kunye neteyiphu ye-polyester yerabha ejikeleze ucingo olukhuselayo kunye nentambo yomhlaba, uyilo lwenkqubo yokukhusela kunye nolawulo lwenkqubo, ulwakhiwo lomgca wokudlulisa ngesantya esiphezulu, iimfuno zokusebenza kombane kunye nethiyori yokudlulisa.

Imfuneko yomqhubi

Kwi-SAS, ekwangumgca wokudlulisa ohamba rhoqo, ukufana kwesakhiwo senxalenye nganye yinto ebalulekileyo ekumiseleni imvamisa yokudlulisa yentambo. Ke ngoko, njengomqhubi womgca wokudlulisa ohamba rhoqo, umphezulu ujikelezile kwaye ugudile, kwaye isakhiwo solungiselelo lwangaphakathi lwelatisi siyafana kwaye sizinzile ukuqinisekisa ukufana kweempawu zombane kwicala lobude; Umqhubi kufuneka abe nokumelana okuphantsi kwe-DC; Kwangaxeshanye kufuneka kuthintelwe ngenxa yentambo, izixhobo okanye ezinye izixhobo ezibangelwa kukugoba rhoqo komqhubi wangaphakathi okanye ukugoba okungaguqukiyo, ukuguqulwa kunye nomonakalo, njl.njl., kumgca wokudlulisa ohamba rhoqo, ukumelana komqhubi yeyona nto iphambili ebangela ukuthotywa kwentambo (iiparameters eziphezulu ze-frequency part 01- attenuation parameters), kukho iindlela ezimbini zokunciphisa ukumelana komqhubi: ukwandisa ububanzi bomqhubi, ukukhethwa kwezinto zomqhubi ohlala phantsi. Emva kokuba ububanzi bomqhubi bunyuke, ukuze kuhlangatyezwane neemfuno ze-impedance ephawulekayo, ububanzi bangaphandle bokugquma kunye nobubanzi bangaphandle bemveliso egqityiweyo ziyanda ngokufanayo, nto leyo ebangela ukunyuka kweendleko kunye nokucutshungulwa okungahambi kakuhle. Ngokwethiyori, xa kusetyenziswa umqhubi wesilivere, ububanzi bangaphandle bemveliso egqityiweyo buya kuncipha, kwaye ukusebenza kuya kuphucuka kakhulu, kodwa ngenxa yokuba ixabiso lesilivere liphezulu kakhulu kunexabiso lethusi, ixabiso liphezulu kakhulu ukuba livelise ngobuninzi, ukuze siqwalasele ixabiso kunye nokumelana okuphantsi, sisebenzisa isiphumo sesikhumba ukuyila umqhubi wentambo. Okwangoku, ukusetyenziswa kwabaqhubi bethusi abafakwe kwi-SAS 6G kunokuhlangabezana nokusebenza kombane, ngelixa i-SAS 12G kunye ne-24G ziqalile ukusebenzisa abaqhubi besilivere.

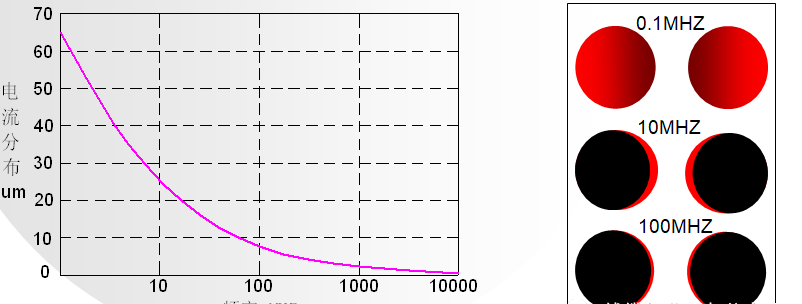

Xa kukho intsimi yamandla atshintshanayo okanye i-electromagnetic etshintshanayo kwi-conductor, usasazo lwamandla ngaphakathi kwi-conductor aluyi kulingana. Njengoko umgama ukusuka kumphezulu we-conductor ukhula kancinci kancinci, uxinano lwamandla kwi-conductor luyancipha ngokukhawuleza, oko kukuthi, amandla akhoyo kwi-conductor aya kugxila kumphezulu we-conductor. Ukusuka kwi-transverse plane ethe nkqo ukuya kwicala lamandla akhoyo, amandla akhoyo enxalenye ephakathi ye-conductor ngokusisiseko yi-zero, oko kukuthi, phantse akukho flow yamandla akhoyo, kwaye kuphela inxalenye esemaphethelweni e-conductor eya kuba ne-subcurrents. Ngamafutshane, amandla akhoyo agxile kwinxalenye "yesikhumba" ye-conductor, ngoko ke ibizwa ngokuba yi-skin effect. Isizathu sale mpembelelo kukuba intsimi ye-electromagnetic etshintshayo ivelisa intsimi yombane ye-vortex ngaphakathi kwe-conductor, ethintelwa yi-current yokuqala. Isiphumo sesikhumba senza ukuba ukumelana komqhubi kunyuke ngokwanda kwesantya sombane otshintshanayo, kwaye kukhokelela ekunciphiseni ukusebenza kakuhle komsinga wokudlulisa intambo, kudla izixhobo zesinyithi, kodwa kuyilo lweentambo zonxibelelwano ezisebenzisa isantya esiphezulu, lo mgaqo ungasetyenziselwa ukunciphisa ukusetyenziswa kwesinyithi ngokusebenzisa ipleyiti yesilivere kumphezulu phantsi kwesiseko sokuhlangabezana neemfuno ezifanayo zokusebenza, ngaloo ndlela kunciphisa iindleko.

Imfuneko yokuvala ubushushu

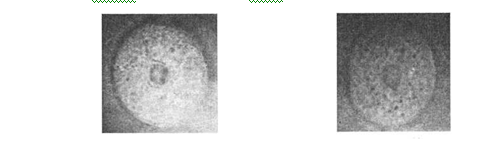

Ngokufanayo neemfuno zomqhubi, i-insulation medium nayo kufuneka ifane, kwaye ukuze kufumaneke i-dielectric constant s ephantsi kunye ne-dielectric loss Ixabiso le-Angle tangent, iintambo ze-SAS zihlala zisebenzisa i-foam insulation. Xa i-foaming degree ingaphezulu kwe-45%, i-chemical foaming kunzima ukuyifikelela, kwaye i-foaming degree ayizinzanga, ngoko ke intambo engaphezulu kwe-12G kufuneka isebenzise i-physical foaming insulation. Njengoko kubonisiwe kumfanekiso ongezantsi, xa i-foaming degree ingaphezulu kwe-45%, icandelo le-physical foaming kunye ne-chemical foaming elibonwa phantsi kwe-microscope, i-physical foaming pores zincinci kwaye zincinci, ngelixa i-chemical foaming pores zincinci kwaye zikhulu:

ukufutha ngokwasemzimbeni Ikhemikhaliukugqwala

Ixesha leposi: Epreli-20-2024